Wood Polymer Extrusion Line Profile (decking) Type SJSJ65/132

WPC Decking production line

WPC decking extrusion line

WPC floor extrusion machinery

WPC wall panel machine

WPC profile extrusion machinery

WPC plastic machine

What is Features of our WPC profile machine?

1.Our WPC machine has features of low consumption,low noise,stable running..

2.This WPC machine include:extruder,mould,vacuum calibration table,haul-off machine,cutter and stacker.

3.The extruder of WPC machine adopt special wpc screw and barrel for extrusion.With different mould,WPC machine

can produce wpc products with different shapes.

Flow Process

1.PE/PP+wood extrusion line craft:

Wood milling(wood powder,rice husk)—— Mixer(plastic+wood)——Granulator——Wpc extrusion line+Auxiliary

2.PVC+wood extrusion line craft:

Wood milling(wood powder,rice husk)——Mixer(plastic+wood)——Wpc extrusion line+Auxiliary

Technical parameter

| Model |

YF180 |

YF300 |

YF600 |

YF800 |

YF1000 |

| Max.width of product(mm) |

180 |

300 |

600 |

800 |

1000 |

| Extruder mode |

SJZ51/105 |

SJZ65/132 |

SJZ80/156 |

SJZ80/156 |

SJZ92/188 |

| Extrusion capacity(kg/h) |

150 |

180 |

360 |

360 |

600 |

| Motor power(kw) |

18.5 |

37 |

55 |

55 |

110 |

| Total length(m) |

18 |

22 |

26 |

28 |

32 |

Main Composition

| Item |

Quantity |

| 1.twin screw extruder |

one set |

| 2.Nosae and Die mould |

one set |

| 3.Vacuum calibration table |

one set |

| 4.Haul-off unit |

one set |

| 5.Cutting unit |

one set |

| 6.Stacker |

one set |

| 7.Electric control system |

one set |

| 8.Spare parts list |

one set |

Application

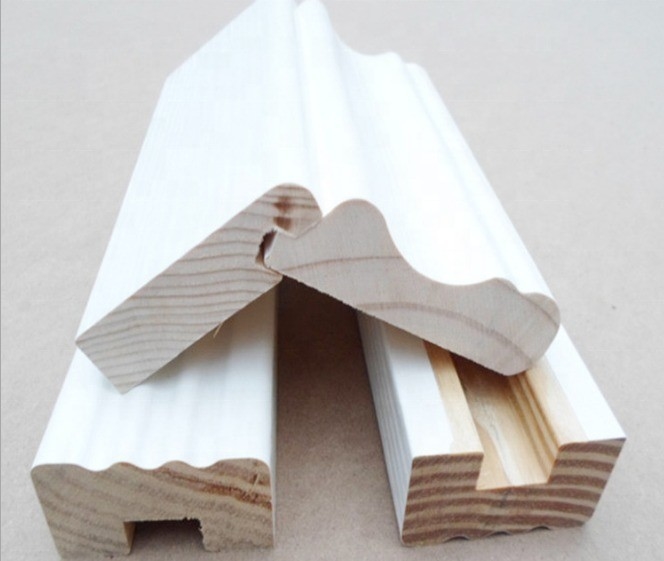

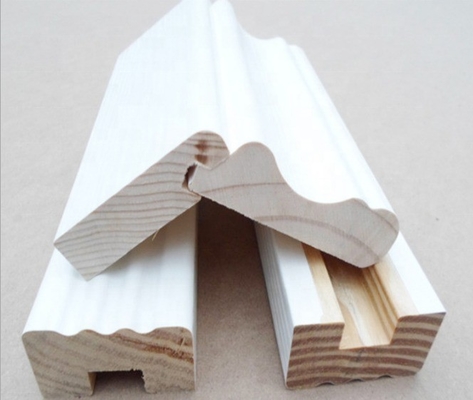

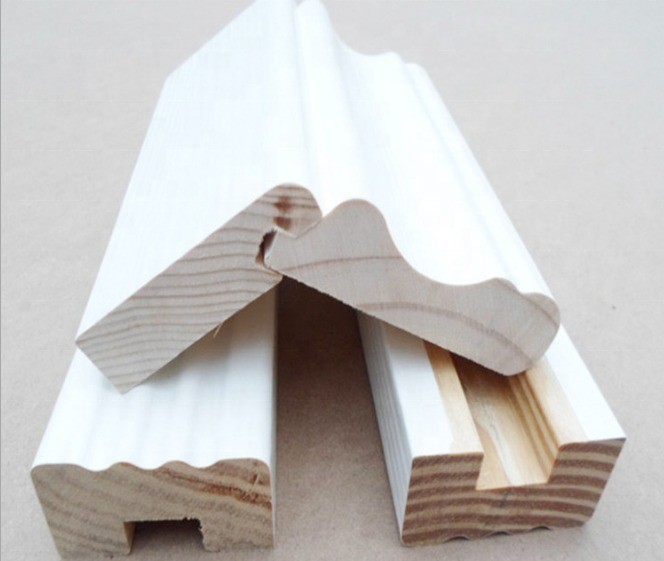

WPC production line is mainly used for producing wpc profiles,such as decking,skirting stair handrails etc.Meanwhile,this production line can also produce pure pvc products,such as door&window frame,ceiling etc.

Machine's Photos

1.Twin screw extruder -- SJZ xx series conical twin screw extruder: (The model according to the sizes of final products to choose )

The specially designed screw and the advanced controlling system ensure excellent plasticization, high output and stable extruding.

2.Die mould

Mould adopts high-quality alloy steel and throttling device to ensure even pressure of feed influent at the mould lips, and also differential action of up-down piece guarantee even thickness of the plate.

3.Vacuum calibration table

Heating exchanging and cooling system of quick speed in calibrating system alternate effectively and ordinally with vacuum system, which ensures calibrating precision. Vacuum system composes two independent subsystems and each is equipped with several fixed circulating vacuum lines of three-point type. Meanwhile, each line carries vacuum regulating system and vacuum display system that realize even and stable vacuum degree of plate surface.

4.Haul-off unit and cutting unit

There are two tractors. The first one is of high powr, high reduction ratio, multi-roller type, well low-speed operation, high traction and is able to draw the plate up from the calibrating table evenly and synchronal. The second one is designed to remove stress, and in addition it is equipped with edge-cutting device to ensure the valid width and smooth cut of the edges.

5.Stacker

6.Electric control system

| Temperatue |

Omron |

| Contactor |

Schneider |

| Relay |

Schneider |

| Transducer |

Holip |

| Power light, button |

Schneider |

| Inveter |

ABB |

Trade Terms

Payment: T/T, Western Union, MoneyGram,PayPal; 30% deposits; 70% balance before deliverying.

Delivery Time: 30-45 days

MOQ: 1set

Package Informations:

Our Certification

Company Review

Imported Electic Parts

Best Services

1.Our company will provide relevant information on various technology and business consulted by customers. If clients want to visit our company, we will offer all they need for convenience.

2.After signing contract, company designs groundsill installation chart for water, electricity and gas of equipment basing on real condition and customers’ requirements and provides detail order list and matching manufacturer for reference for customer.

3.After equipment arrival, our service personnel will arrive at posted locale for installation, debugging, training and technology transfer till customers can operate independently and manufactures eligible product. Service personnel have to arrive at customer’s locale in time when we provide service for client again.

Why Choose us

1.We are China Leading Plastic Machine Manufacturer.

2.Alibaba Assessed 7 years Domestic Supplier .

3.Inspected by the Inspection Institution of SGS Certification.

4.100% QC inspection Before Shipmeng.

5.Best Quality & Best Service with Competitive price.

We have two this production lines in our showroom for other customer , welcome to visit our factory

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!